Axel Arigato - 3D Design

Intro

In late 2024, I was contacted by Axel Arigato's Head of Footwear Design after she discovered my work on Instagram. What began as a single trial project evolved into an ongoing contract relationship where I serve as their on-demand 3D specialist, brought in when projects require technical modeling, visualization, or design development support that isn't available in-house.

This case study focuses on a released project: a set of five lace charms designed for the Axel Arigato Eris sneaker launch campaign. These small accessories showcase the technical precision and rapid turnaround that defines my work with the brand.

Skills:

The Challenge

Create five distinct lace charms to exact specifications that would be:

3D printable for immediate campaign use in retail stores

Production-ready to serve as the basis for injection-molded versions later

Structurally sound enough to function as wearable accessories

Delivered quickly to meet tight campaign timelines

The charms needed to balance creative expression with technical constraints; they had to look good, work mechanically, and be manufacturable at scale.

The Concept

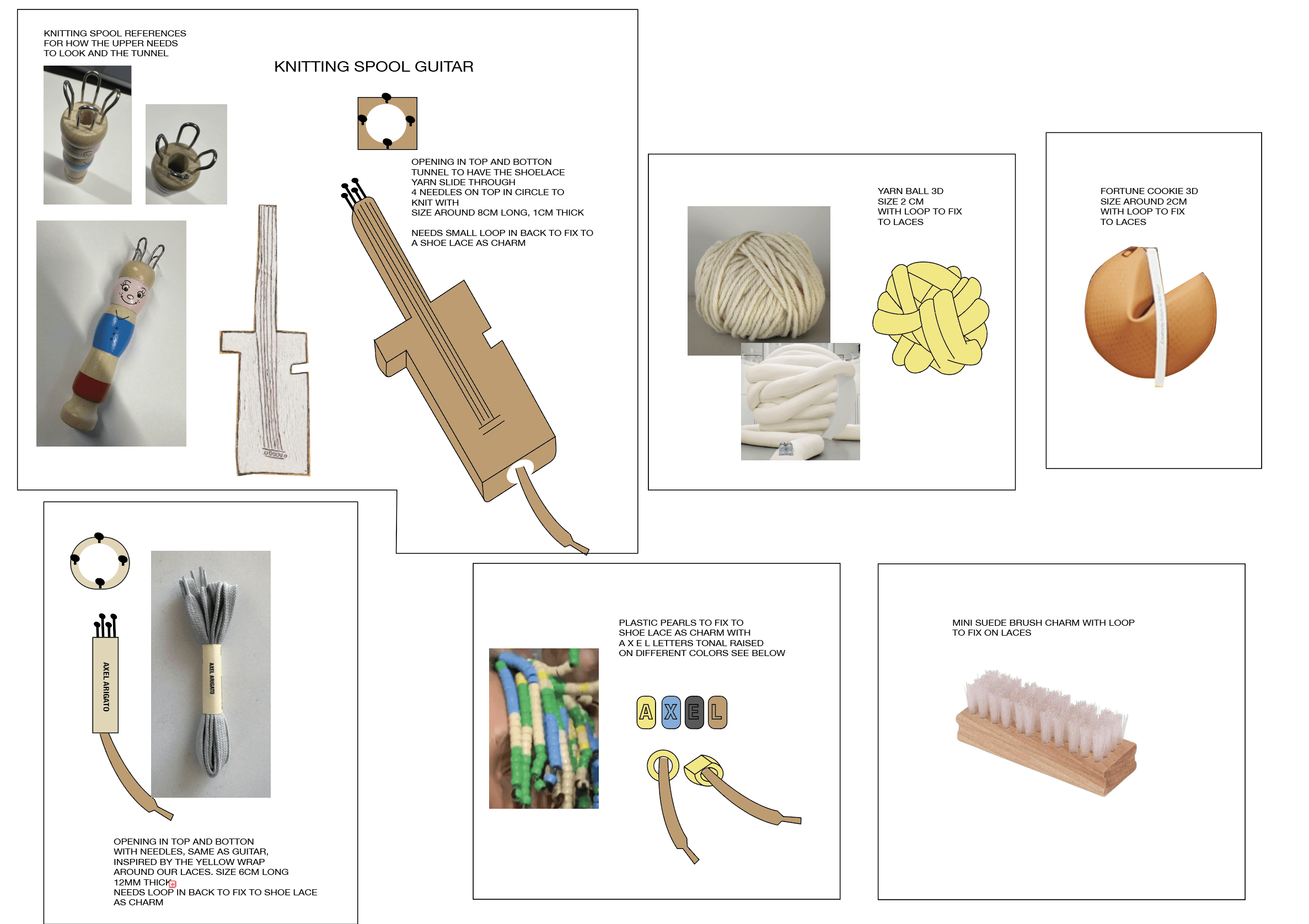

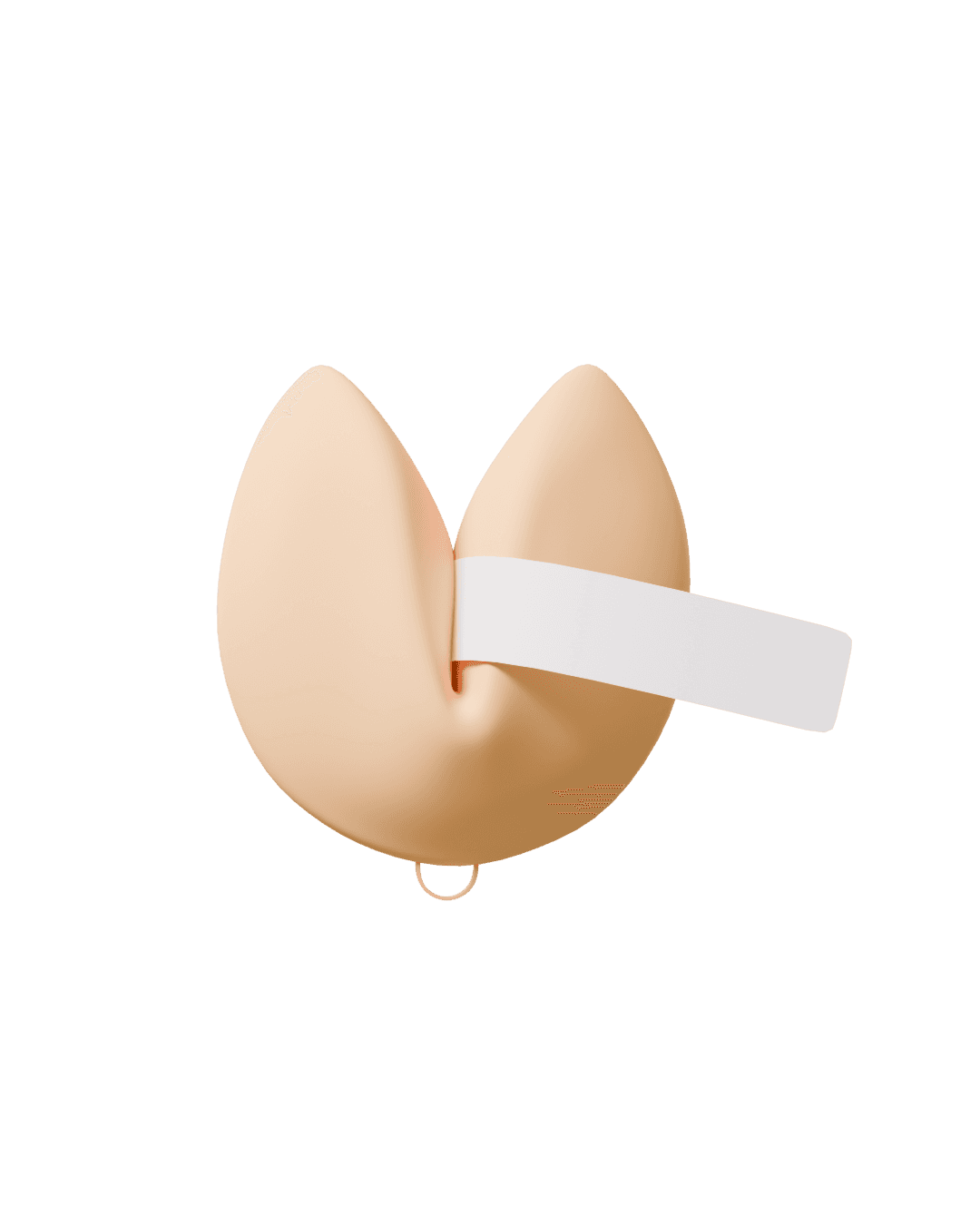

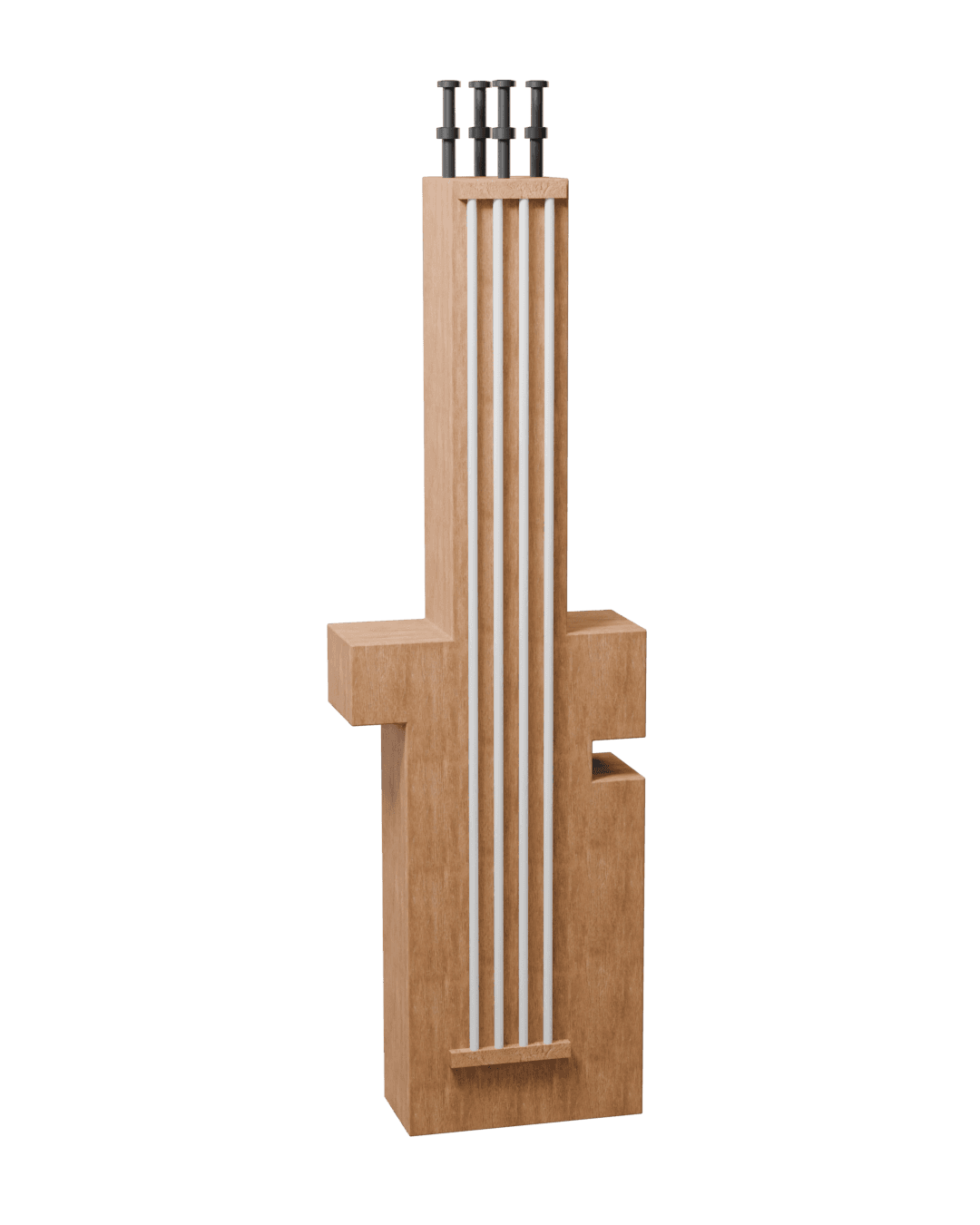

The lace charms were designed as part of Axel Arigato's Eris sneaker launch strategy, allowing customers to personalize their shoes with unexpected motifs. Rather than typical sneaker accessories, the charms featured distinctive objects: A guitar, brush, yarn ball, and other unconventional elements that let wearers express individual style.

When purchasing Eris sneakers in-store, customers could select whichever charms resonated with them, creating unique combinations that transformed the shoe from product to personal statement.

Design Process

Understanding Requirements

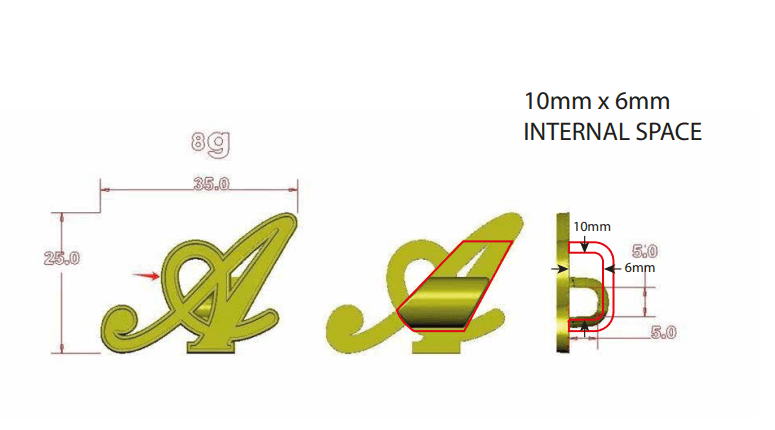

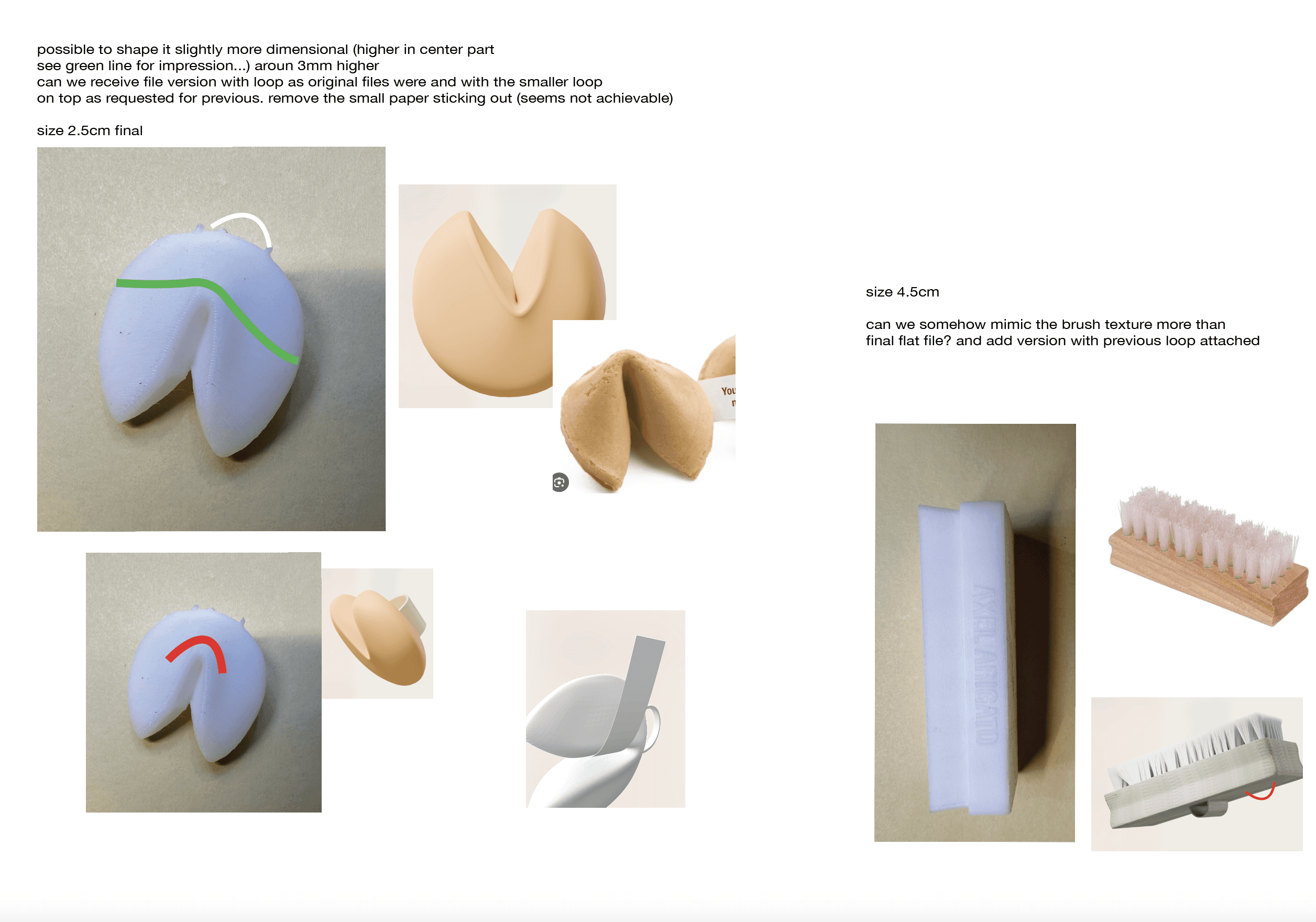

The project began with detailed specifications and 2D reference sketches from Axel Arigato's design team. My role was translating these concepts into precise 3D models while ensuring technical feasibility. Some designs came with exact dimensions and forms to match, while others gave me interpretive freedom in how the 2D sketch would work in three-dimensional space.

Understanding the dual purpose of immediate 3D printing and future injection molding, meant considering manufacturing constraints for both processes from the start.

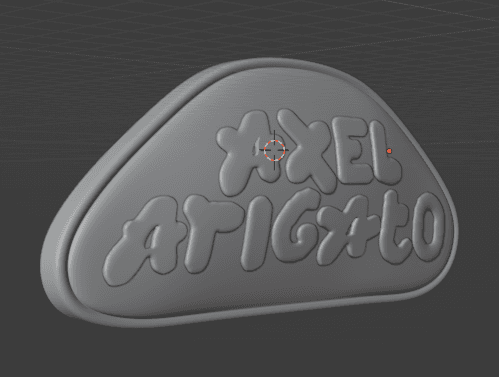

3D Modeling

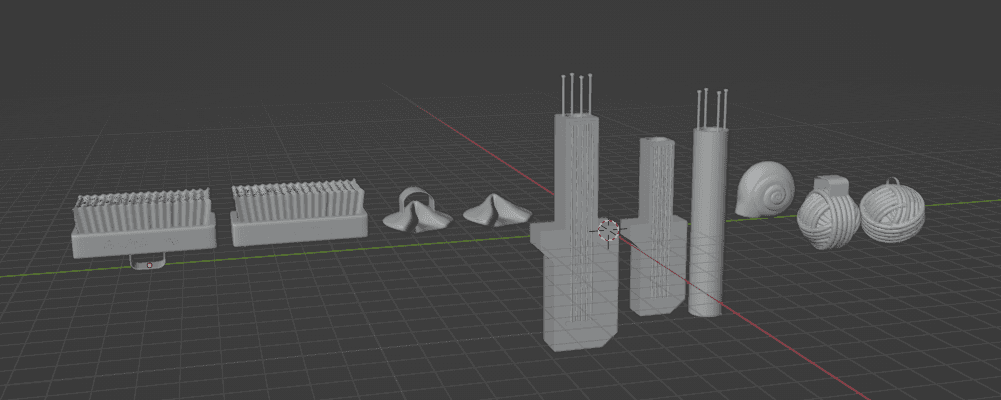

I modeled most charms in Blender for precision control, but switched to Gravity Sketch in VR for pieces with highly organic forms. VR modeling proved valuable for shapes that were difficult to manipulate with traditional 3D tools, allowing me to sculpt intuitively and maintain natural proportions.

The key technical challenge was creating functional lace holes. While conceptually simple, modeling clean circular holes manually creates unnecessarily complex mesh topology. I used a Boolean workflow to subtract perfect cylinders from the base geometry, which worked well but required careful mesh cleanup to ensure 3D printability.

Technical Refinement

Each charm needed to balance structural integrity with aesthetic goals. Because they would be worn on shoes, subject to movement, tension, and occasional impacts, they couldn't be fragile. But making them too thick would compromise the design.

This meant carefully considering:

Wall thickness: Strong enough to withstand use, thin enough to maintain proportions

Lace hole dimensions: Large enough for standard laces, positioned to hang correctly

Overall mass distribution: Preventing weak points where stress would concentrate

Print orientation: How the charm would be positioned during 3D printing to minimize support needs

Iteration & Testing

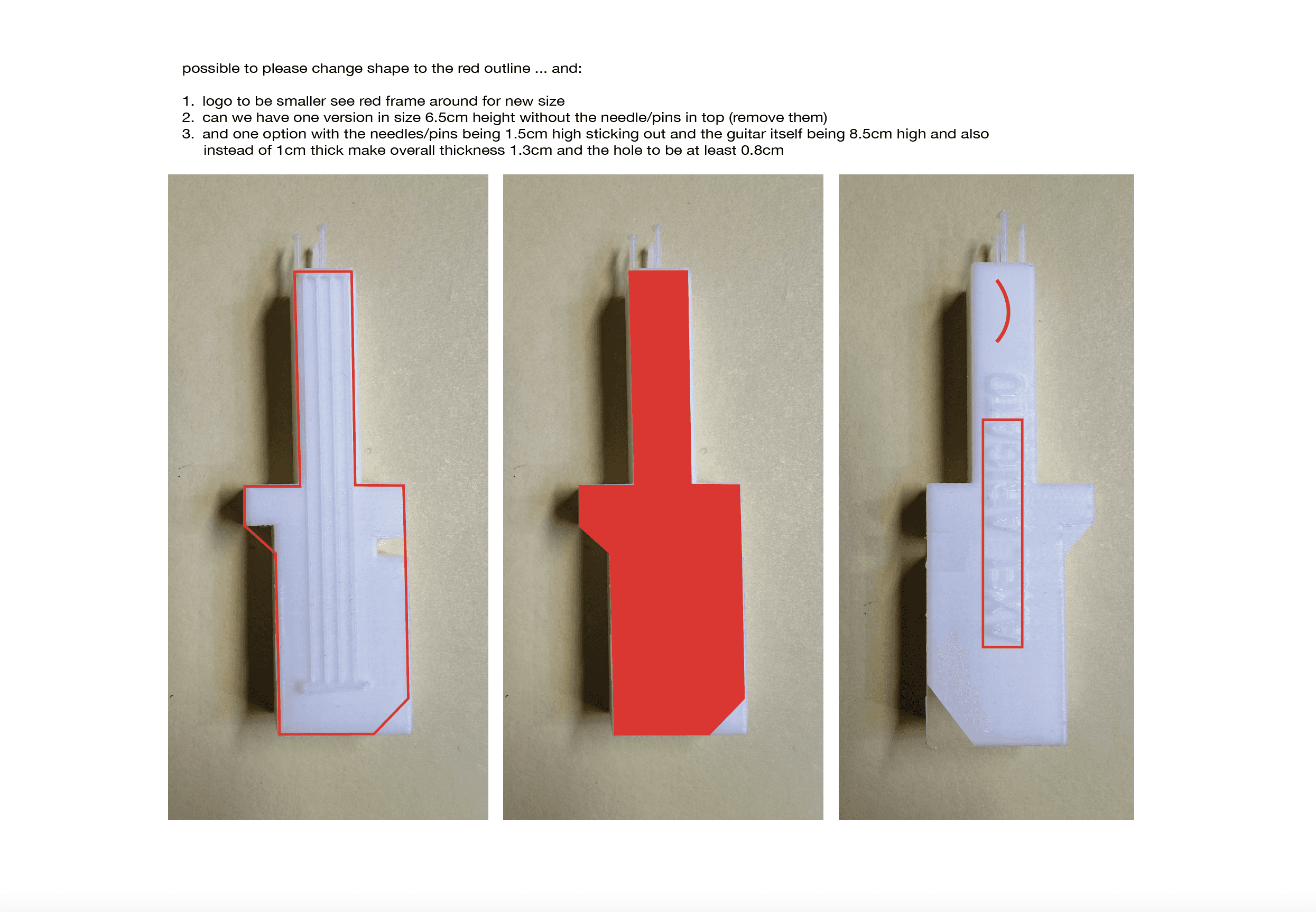

I delivered initial models to Axel Arigato, who produced test prints at their headquarters. Based on physical testing, we refined:

Sizing adjustments to ensure proper scale on the shoe

Lace hole positioning and diameter

Surface details and proportions

Structural reinforcements where needed

This feedback loop happened quickly. I'd receive notes in the morning and deliver revised files by afternoon. Speed was critical to keeping the campaign timeline on track.

Final Production Files

Once approved, I delivered final 3D models optimized for both immediate PLA 3D printing and future use as templates for injection mold creation. The files needed to be clean, properly scaled, and documented for the manufacturing team to work from without additional designer input.

Outcome & Reflection

The lace charms launched successfully as part of the Axel Arigato Eris campaign, available to customers purchasing sneakers in-store. The project exemplifies the type of technical design work I provide for Axel Arigato, translating creative vision into manufacturable reality with rapid turnaround.

What I Learned:

Speed is a Professional Skill: Working with a brand at Axel Arigato's scale taught me that execution speed is as valuable as design quality. The ability to turn around iterations in hours rather than days directly impacts project timelines and budgets. This has become one of my defining strengths.

Communication Clarity is Critical: When working remotely on technical projects, misunderstandings are expensive. I learned that over-communication is always better than under-communication.

Design Within Constraints is Still Design: While I wasn't designing these charms from scratch, the process of translating 2D concepts into functional 3D objects required constant design decisions; proportions, surface transitions, structural logic, how details would read at scale. Technical execution is creative problem-solving.

Versatility Opens Doors: This relationship with Axel Arigato has expanded beyond footwear into unexpected territories. Recent projects have included everything from organic forms (modeling a bird head for one project) to various product categories, like handbags, and accessories.

Professional Impact:

Beyond this specific project, my work with Axel Arigato demonstrates my ability to:

Work within established brand systems and follow precise specifications

Deliver production-ready files that manufacturers can use directly

Maintain quality under tight deadlines

Communicate effectively with design teams

Adapt to diverse project requirements

Additional Work Under NDA

Since beginning this relationship in late 2024, I've contributed to 5 additional footwear and accessory projects for Axel Arigato, including:

Modeling and visualizing a slip-on mule design

Modeling and visualizing a traditional suede shoe

Modeling and visualizing an untraditional handbag concept

Developing and modeling an experimental tooling construction

Developing and modeling 3D printed assets for an upcoming collaboration

Due to the confidential nature of unreleased work and long footwear development timelines, I'm unable to share details or visuals of these projects. However, they represent ongoing collaboration on both released and exploratory concepts where my 3D expertise supports Axel Arigato's design process.